How To Cope Moulding for a Better Joint

When installing molding into an inside corner,

many people just cut the two pieces with a 45° angle and then fasten

the pieces into the corner. The problem with this is that the joint tends

to open up over time. It isn't a big deal, but it looks sloppy. Also,

most corners aren't precisely 90°, so unless you take the time to

measure the angle and then split it evenly between the two pieces, it

isn't go to look good either. Even then, the joint will still open up.

The better approach is to use coped joints. That is where the end on

one piece is cut to precisely match the profile of the other section

of molding. It sounds complicated, but it is easy, if you know the

trick. The results look professional and the joint isn't going to open

up later. You will need a coping saw; a special saw with a very fine

blade. Don't worry, you can buy one for less than ten dollars and they are worth the small investment.

The first piece of molding is cut to the full length to fit the wall

(or whatever) and cut with a regular 90° cross cut and then installed.

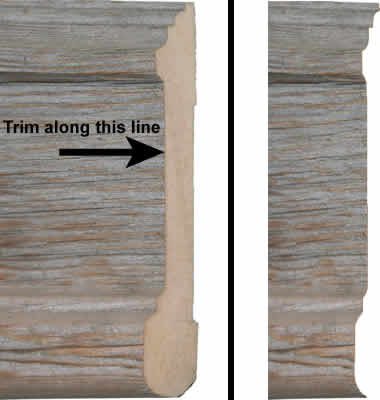

The trick comes with the piece being coped, cut the end with a 45° angle,

just as though you were going to do a simple joint. Now if you look at

the piece of moulding, you will see the cut line on the face (see the

photo). Use the coping saw to cut along the line and you will be left

with a near perfect mate to the face of installed molding.

When making the cut, it helps to back-cut the profile, that is, instead

of cutting at a 90° angle to the face, cut at about 91° or 92°.

This allows you to snug the piece into the profile of the matching moulding

and minimize any joint line.

One thing to consider when choosing which piece to be coped is people's

view of the joint. If people will view the joint from one angle more

than another, the less viewed piece should be one coped. The reason being,

if you do less than a perfect job on the cut, it will be less visible.

Another consideration, if you will cope both ends of a piece, cut it

to length with 45° angles on both ends, so that it fits snugly in place. When you cope the ends,

cutting right on the line should yield a piece that pieces nicely between

the installed moulding. |

|

|